Aluminum is the material used in the casting industry and known for its durability. The reason for its use is that the wood or other model process has a long service life compared to the types of materials used, it is suitable for practical use and it is unlikely to be affected by environmental factors. The full rolling materials used in the construction phase increase the quality of the model to be produced. Before starting the model process, it is examined by our expert units in the field of technical drawing of the product to be delivered to our company by the buyer.

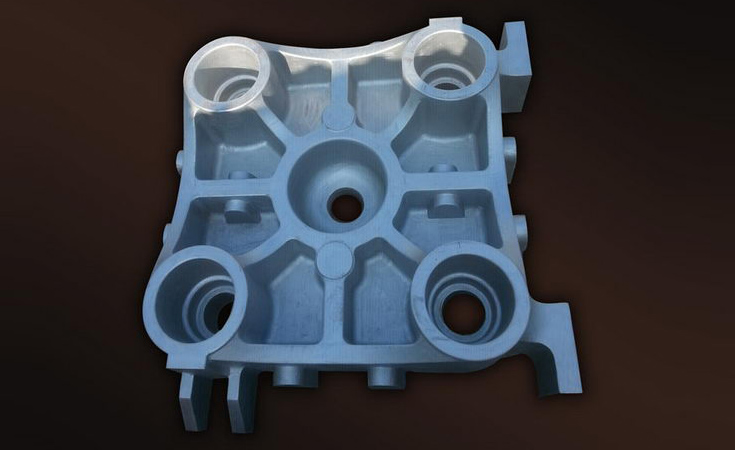

In the technical drawing, the structure of the model, the size of the model and the size of the materials to be used are determined. Our company creates the design of the models to be produced by pouring concrete objects or imaginary parts into visual shapes with 3D design programs. One of the important factors determining the use of aluminum material is the number of production. To explain, if there is a high number of production and the desired model will be produced continuously, aluminum material is preferred.

The product in question is primarily designed from wood. If it is explained in a clearer language, the mdf view of the desired model is designed and previewed. In other words, the image of the model to be made using aluminum material on mdf is examined. In the mdf design of the product, the necessary process shares are left and the model is started to be produced from aluminum material. The release of the processing shares is the measure taken to prevent any exceeding of the desired dimensions as a result of the high temperature exposure of the aluminum material during casting. With this process, the possibility of pulling of aluminum, ie shortening is solved. The processing shares are determined according to the type of material to be poured, according to the surface hardness of the same material and the size of the surfaces to be processed. According to the type of material to be given at least 3 millimeters and the size of the process to be given according to the size of the process should be 8-12 mm. Aluminum model process is thus more healthy and efficient.

All processes to be performed on the CNC machine are applied in the light of predetermined measurements and all precautions are taken for possible problems. After the design of the aluminum model and the processes on the CNC machine are completed, the product is sent to the foundry. By applying the casting process, the final appearance of the desired model is obtained and mass production is started. An important detail is that ready-made molds are used in the production of some aluminum models. If the geometric shape of the desired design is suitable, the use of ready-made molds increases both the production speed and the cost ratios.

All transactions made by our company are implemented in a controlled manner and a rigorous study is carried out in terms of customer satisfaction. Aluminum materials are preferred in terms of both durability and long-term use.